Timber Frame

Quality Timber, Exceptional Solutions

“DG Timber Solutions have expertly crafted timber frames for over a decade, where quality and innovation meet sustainability in every panel”

Timber Frame construction is now being recognised as reliable and incredibly fast compared to traditional methods. It has become the first choice with Developers and Builders alike. Timber frames can decrease the build programme time by as much as 30%. This allows the structure to be watertight in significantly less time than a traditional build.

The manufacturing and construction of Timber Frame is significantly faster than that of traditional building, improving productivity and ensuring cost savings. Read more about timber frames below:

Today, a timber frame structure typically means building using prefabricated walls, floors, and roofs based on the following typical build-up and materials:

- External walls - Breather membrane on 9mm OSB sheathing on 38x140mm CLS timber framing c/w pre-formed window and door openings.

- Internal and Party walls - 38x89mm CLS timber framing c/w pre-formed door openings

- Floors - Flooring grade chipboard on engineered wood joists

- Roofs - Trussed rafters with metal tooth plate connectors

- Flat Roofs – Plywood on Engineered wood joists

Enhancements to this basic “open panel” timber frame structure will improve the system’s performance, particularly with respect to thermal insulation and air tightness. They can also significantly reduce the amount of on-site work required to complete each building. The range of enhancements is extensive, from insulation to external walls to air-tightness detailing such as vapour control layers and service battens—all factory-fitted.

Benefits of Timber Frames

We also offer factory-manufactured floor cassettes, resulting in far safer and faster builds once we reach the site

Benefits of Timber Frames

- Components are manufactured in our Northamptonshire-based factory so that a house can be erected in as little as 48 hours after delivery to the site.

- Reduce site preliminary costs.

- Respond to the market quickly by enabling a rapid “build to order” site operation. It should be no surprise that several national housebuilders have gone on to use this method across their sites and have their own timber frame factories to enable it.

- With timber frame components delivered on a “just in time” basis, building sites are easier to maintain and keep tidy.

Not only is the process of on-site erection rapid and straightforward, but several other benefits also emerge from employing timber frame structures:

- Reduced dead loads and consequent reductions in foundation costs allows marginal sites to be developed.

- Timber frame structures afford exceptionally high insulation standards, with less impact on valuable living space and building footprints.

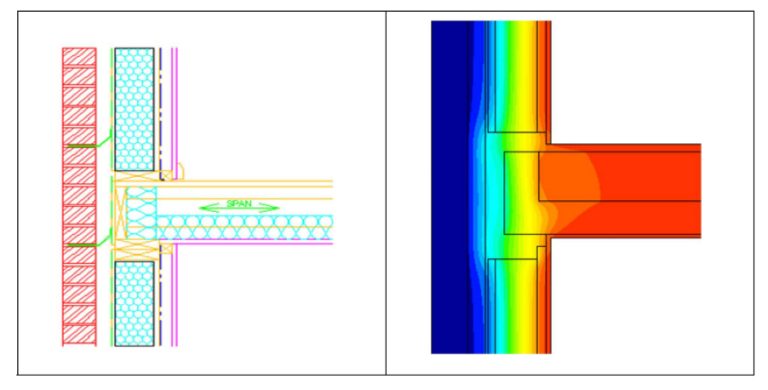

- Thermal bridging details are calculated using thermal modelling software, and Psi values are available upon request.

- Construction progress is not adversely affected by poor weather conditions.

- Snagging and maintenance costs are substantially reduced due to ‘dry’ construction, and now, with the everyday use of “engineered wood” in floors, the need for follow-on trades to make allowances for shrinkage has been reduced.

- Thanks to timber frames' low thermal conductivity, low U-values and Passivhaus performance standards can all be achieved.