Our Services

Quality Timber, Exceptional Solutions

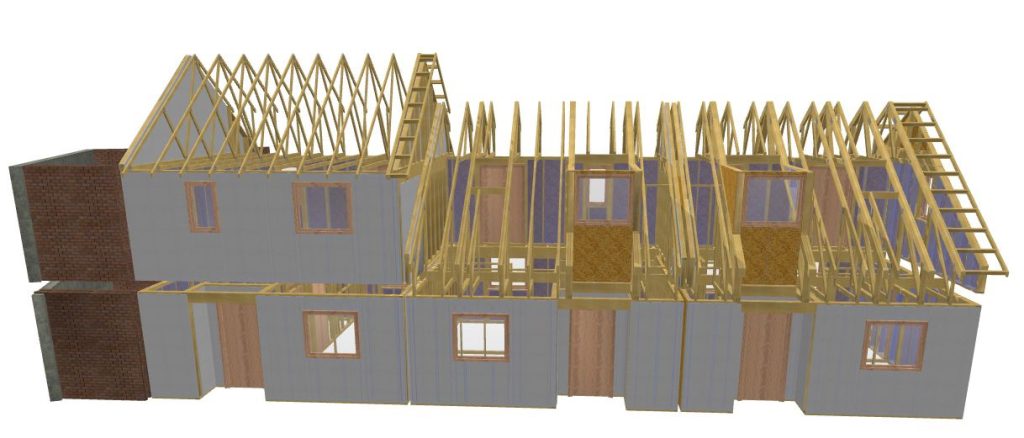

DG Timber Solutions provides tailor-made packages to meet any specification. Whether you’re a main contractor, a developer looking for a long-term supplier partnership or a self-builder looking for timber frame services, we can help. We can offer any of the following Timber Frame options: -

- Design, manufacture and construction

- Design and manufacture

- Manufacture only

Design

We use specialist consultant structural engineers who understand the unique physical properties of Engineered timber products and to realise straightforward and cost-effective designs.

Using the structural engineer’s appraisal, our in-house design team expertly transforms your architectural drawings into timber frame elements. We produce detailed wall components and layouts using specialist timber frame design software, while MiTek’s Pamir allows us to design roof trusses and floor joists. We ensure that all work adheres to current industry and governing standards, maintaining meticulous attention to detail throughout the entire process.

We can offer both open and closed-panel Timber frame solutions with u-values as low as 0.10 W/m²/K. All our panel options have been thermally modelled to meet the latest regulations required in the Standard Assessment Procedure (SAP) for new homes in England and Wales.

Manufacture

From our Northamptonshire manufacturing facility, we fabricate high-quality, precision-made wall and floor sections using CAD/CAM outputs from the latest design software packages. We can offer fully insulated wall panels and floor cassettes with either open metal web or I-joists.

For roof trusses, we work with specialist fabricators only, who, as trusted long-term partners, bring the same high standards of service and quality.

Visits to our manufacturing facility are welcome – please contact us if you wish to arrange this.

Construction

We only use highly qualified installers who are Structural Timber Association (STA) certified. This ensures we maintain the highest gold standard for all projects.

All projects are programmed in agreement with our clients and installers to achieve seamless delivery and installation. This also supports the client’s overall build program and follow-on trades.

Once programs have been formulated, the factory will build them and deliver them to the site. We predominantly use cranes to install the timber frame, but alternative options may be used if sites have restricted access.

The main benefits of timber frames are speed and quality. The panels are built off-site and are checked throughout the manufacturing process. We conduct a thorough snagging and quality procedure with our onsite installers before the builds are handed over to our clients.